Corn to Cork Tour

As I mentioned in my Kentucky trip overview post a few weeks ago, I paid $30 for the two hour Woodford Reserve Corn to Cork Tour and tasting. The tour was definitely worth the $30 and I highly recommend it to anyone with an interest in making whiskey. Our guide, a young woman named Stacy, was extremely well versed in the details of the distillery and its operation. She was able to answer all but one question which made this tour the most informative tour of all the tours we enjoyed on this trip.

The only question she left unanswered concerned the production split between the Woodford Reserve Versailles facility and the Brown-Forman distillery in Louisville. In case you were not already aware, much of the distillate that ends up in a Woodford Reserve bottle comes from the Louisville facility. The details of that production split appear to be a closely guarded corporate secret. Also, while the Versailles facility uses cypress fermentation tanks and copper pot stills, the Brown Forman Louisville facility uses stainless steel tanks and a column still.

The Ingredients for Woodford Reserve

The four essential ingredients for any whiskey are the water, the mash bill, the yeast, and the barrels. The Versailles facility uses filtered well water for distilling. This allows the master distiller to take advantage of the minerals in Kentucky’s famous limestone filtered water during fermenting. Later, when it’s time to dump the whiskey from the barrels and bottle it, Woodford Reserve uses purified water from a reverse osmosis machine to cut the whiskey to the desired bottle proof. Using this demineralized water ensures the water doesn’t affect the whiskey’s flavor or aroma profiles.

The Versailles facility uses three primary mash bills; one for bourbon, one for rye whiskey, and, one for their newest product, malt whiskey. The bourbon mash bill consists of 72% corn from a single source in Kentucky, 18% rye from suppliers located in northwest United States, and 10% malted barley also sourced from northwest US. This very high corn mash bill tends to result in a sweeter final product than bourbon with mash bills with a higher rye content such as Jim Beam Old Granddad Bourbon at 63% corn and 27% rye. The rye mash bill, at 53% rye from northwest US, 33% corn from Kentucky, and 14% malted barley from the northwest US produces a very bourbon like rye whiskey. Woodford Reserve’s newest major product is its Straight Malt Whiskey with a mash bill of 51% malted barley from northwest US, 47% Kentucky corn and 2% rye from northwest US.

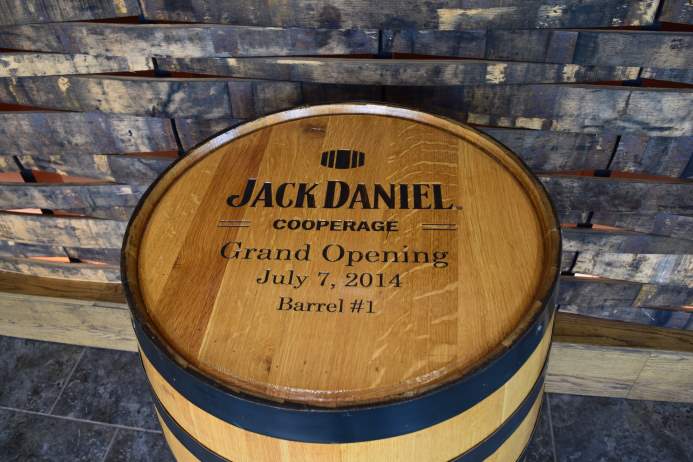

Woodford Reserve propagates its own jug yeast at the Versailles facility. This yeast, which dates to 1929, is used to obtain their desired fruit and floral flavor profile. The Versailles facility receives one teaspoon of frozen stock from Brown-Forman every 3 months to ensure consistency. During the Corn to Cork Tour we were allowed into the Quality Control room and shown how they propagate the yeast. All Woodford Reserve barrels are produced at the Brown-Foreman Louisville Kentucky cooperage. The barrels are toasted before receiving a medium char.

The Whiskey Making Process at the Versailles Facility

All grains received at the Versailles facility are ground on site using a hammermill. The ground grains, along with well water and some of the backset from a previous distilling run, are added to the mash tun for cooking. Adding the backset, known as the sour mash technique, helps maintain the Ph of the water, adds nutrients beneficial to fermentation, and reduces water and utility costs. Once cooked, the mash is pumped into one of their 7500 gallon cypress fermentation tanks. The yeast is added and the mash is allowed to ferment for up to seven days. While Woodford Reserve’s marketing highlights the importance of the cypress to their whiskey, it is important to not lose sight of the fact that much of the Woodford Reserve product is distilled in the Louisville facility where stainless steel fermentation tanks are used. The cypress tanks have coiled steel tubes running along the inside to cool the fermenting mash to a temperature of about 85o. The folks at Woodford Reserve believe the longer fermenting duration, most distillers use three days, results in a more flavorful final product. The fermentation tanks are steam cleaned after every batch. Once fermentation is complete, the fermented mash, called distiller’s beer, is pumped to the beer well and it’s time to start distilling.

The mash is triple distilled using the three gorgeous copper pot stills. The first, called the beer still, produces a distillate at about 30 proof. As the alcohol vapor condenses it moves into a holding tank. Once a batch is ready in the holding tank, the distillate is pumped into the high wine still which raises the distillate up to about 100 proof. Some cuts are made as the distillate comes off the high wine still, but most of it is passed along to spirits still. The spirits still produces distillate at about 158 proof, which is quite high for bourbon. Most other distillers go no higher than 140 proof. Woodford Reserve cuts out most heads and cuts deeply into the tails, focusing on the hearts to give the final product its strong fruit and floral notes. The heads and tails are recycled into the next batch run to ensure the distillery extracts as much usable alcohol from each fermented batch of mash.

The mash is triple distilled using the three gorgeous copper pot stills. The first, called the beer still, produces a distillate at about 30 proof. As the alcohol vapor condenses it moves into a holding tank. Once a batch is ready in the holding tank, the distillate is pumped into the high wine still which raises the distillate up to about 100 proof. Some cuts are made as the distillate comes off the high wine still, but most of it is passed along to spirits still. The spirits still produces distillate at about 158 proof, which is quite high for bourbon. Most other distillers go no higher than 140 proof. Woodford Reserve cuts out most heads and cuts deeply into the tails, focusing on the hearts to give the final product its strong fruit and floral notes. The heads and tails are recycled into the next batch run to ensure the distillery extracts as much usable alcohol from each fermented batch of mash.

The finished distillate is pumped to the gauging tank where water is added to bring the proof of the product to the desired strength for barreling. The barrels of raw whiskey, whether from the Versailles or Louisville facility, are stored in Woodford Reserve’s rickhouses. Unlike most distilleries, Woodford Reserve uses steam to heat the rickhouses in cycles during winter to improve maturation. After the whiskey has aged sufficiently, the barrels are brought to the bottling line where they are dumped and the whiskey placed into a batching tank. The number of barrels, and whether they originated at the Versailles or Louisville facility, is managed by the distillery to achieve a consistent product that meets their standards. A typical batch contains between 120 to 140 barrels. The whiskey is chill filtered to remove compounds which can cause the whiskey to become cloudy during storage and transportation.

The Tasting

After the Corn to Cork tour was complete we returned to the visitor center to taste three Woodford Reserve products; Woodford Reserve Bourbon, Woodford Reserve Double Oaked Bourbon, and Woodford Reserve Straight Rye. I was underwhelmed with the bourbon and rye, but absolutely loved the Double Oaked Bourbon.

After the Corn to Cork tour was complete we returned to the visitor center to taste three Woodford Reserve products; Woodford Reserve Bourbon, Woodford Reserve Double Oaked Bourbon, and Woodford Reserve Straight Rye. I was underwhelmed with the bourbon and rye, but absolutely loved the Double Oaked Bourbon.

This was a fantastic tour experience, due in large part to our guide Stacy’s deep and broad knowledge of the distillery. I highly recommend taking this tour instead of the standard consumer tour. It’s well worth the $30 fee.